- JP

- EN

Technologies to Prevent Global Warming (CO2 Reduction)

- MOL Sees Encouraging Results in Test of Heat-Shielding Paint on Large Vessel -

Benefits include energy saving and reduce maintenance costs

September 10, 2008

TOKYO - Mitsui O.S.K. Lines, Ltd. (MOL, President: Akimitsu Ashida) today announced test results showing the benefits of a heat-shielding paint that can save fuel, reduce CO2 emissions, and reduce long-term vessel maintenance costs. The Technology Research Center in MOL's Technical Division completed a yearlong test of heat-shielding paints from 10 manufacturers. Along with group company M.O. Engineering Co., Ltd., MOL applied a test coating of the highest-rated paint to the deck of a large ferry. The test confirmed that the paint effectively reduced temperatures inside the ferry and saved electricity by reducing the load on the vessel's air conditioning system.

The heat-shielding paint used for the test helps block heat generated by sunlight. In addition to improving passenger and crew comfort, boosting air conditioning efficiency, and cutting CO2 emissions, the paint is durable and weatherproof, and will cut ship maintenance costs. The paint is already used on land for buildings, large bridges, factories, tanks, plants, warehouses, vehicles, and railroads. However, this test markets the use on a large vessel.

Characteristics and effects of heat-shield paint

- Characteristics

High vibration is generated and changes it heat energy when sunlight hits a painted surface and infrared rays are absorbed into the coating. This paint uses a special pigment that reflects sunlight, preventing the buildup of heat energy. - Energy-saving effects

The heat-shielding paint prevents the intrusion of heat energy, limiting temperature increase inside of the structure when applied to roofs and other areas exposed to direct sunlight. This reduces electricity consumption by the air conditioning system and saves fuel running the onboard power generator. - Ultra weatherproof

The heat-shielding paint has superior durability against deterioration by sun's ultraviolet rays, thanks to its ultra weatherproof fluorinated formula. Compared to other general-marine paints, the re-painting cycle is very long - 15 to 20 years - and can retain the heat-shielding effect for long periods, which contributes to reduction of maintenance cost.

Verifying the effects of heat-shielding paint

- Test period:

- June to August 2008

- Test vessel:

- Sunflower Gold (11,178 DWT), operated by Diamond Ferry Co., Ltd. between Kobe and Oita

- Paint tested:

- ZEFFLE heat-shielding paint (white), a product of Daikin Industries, Ltd. Chemical Division

- Verification method:

- The heat-shielding paint (white) was applied on 800m2 of the ship's deck (upper part of eight first-class staterooms, crew quarters, and bridge), and compared with surface temperatures of the parts where general-marine paint was used. Researchers then compared the temperature increase/decrease inside the crew quarters of the sister vessel Sunflower Pearl which was coated with general-marine paint. Furthermore, the effects of the measured values were assessed by Daikin Industry's heat-shielding paint effect simulation for land buildings. (Editors: Refer to attachment 1.)

- Verification results:

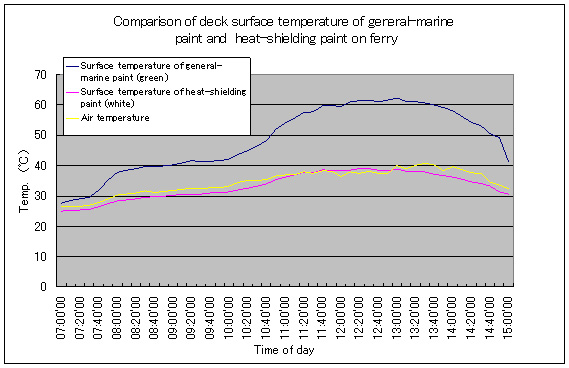

- 20℃ or higher heat-shield effects were confirmed in the comparison of deck paint surface temperature of the heat-shielding paint (white) which the MOL Technology Research Center judged to be the most effective paint, and general-marine paint (green). The increase/decrease of indoor temperature at the peak time of outdoor temperature showed a 5.5℃ effect in the heat-shielding paint effect simulation. The test also confirmed that the burden on the air conditioning system was reduced by 47.7% more than in an on-land air conditioning system, based on the heat shielding and indoor temperature reduction effects measured in this test. That translates into an annual reduction of 8.9 tons of CO2 emissions, and a savings of about 2.2 tons of C oil just from using heat-shielding paint on 800m2 of the deck covering the crew quarters. The heat-shield paint effect simulation is used for land buildings, and heat absorbing efficiency and place of use differ from a vessel (which have decks made of steel plate and operate in high temperature areas such as close to the Equator). That indicates that future savings could be even greater than achieved in the recent test.

Looking ahead

MOL confirmed that the heat-shielding paint significantly reduced energy consumption energy for the air conditioning system. In the future, MOL will take a proactive approach to using this paint on decks of MOL Group ferries, cruise ships, and car carriers. It will also help reduce loading temperatures aboard tankers. In addition, it helps the MOL Group achieve its goals of reducing CO2 emissions, saving fuel, and reducing maintenance costs, thanks to its superior durability.

(graph)

Attachment 1

Comparison of deck surface temperature of general-marine paint and heat-shielding paint on ferry

- Surface temperature of general-marine paint (green)

- Surface temperature of heat-shielding paint (white)

- Air temperature

Temperature (℃)

Time of day

Heat-shielding and general-purpose paint deck temperature comparison data