- JP

- EN

Terminal Business

Owned-operated Terminals Play a Key Role in Container Transport Value Chain

Outline of Services

The MOL Group not only operates container terminals in five ports-Tokyo, Yokohama, Nagoya, Osaka, and Kobe, but also offers cargo handling services for car carriers and other cargo ships in Japan as part of our comprehensive approach to the terminal business. The group also operates container terminals in seven ports overseas (three in the U.S., two in Vietnam, one in Thailand, and one in the Netherlands).

The MOL Group promotes automated and hybrid operation of cargo handling at its facilities, striving to ensure safe, efficient, and environmentally friendly operations.

History

| 1969 | Osaka International Container Terminal (OICT) opens at Nanko Berth C2. |

|---|---|

| 1971 | Tokyo International Container Terminal (TICT) opens at Ohi Berths No. 4/5. |

| 1972 | MOL establishes Nagoya Container Berth Co., Ltd. (NCB) as a participant in the business. |

| 1974 | Kobe International Container Terminal (KICT) opens at Berths PC-7/8/9. |

| 1986 | Yokohama International Container Terminal (YICT) opens at Honmoku Pier D-5. |

| 1987 | TraPac Los Angeles Terminal opens. |

| 1990 | TraPac Oakland Terminal opens. |

| 1991 | TIPS Laem Chabang Terminal Berth No.4 opens in Thailand. |

| 1996 | KICT relocates to high-specification Berths PC-14/15 in the Port of Kobe. |

| 2001 | TICT starts operations at new Berths No.3 and 4 after redevelopment. |

| 2005 | Tobishima Container Berth (TCB) of Nagoya opens. |

| 2009 | TraPac Jacksonville Terminal opens. |

| 2011 | Tang Cang Cai Mep International Terminal (TCIT) opens in South Vietnam. KICT relocates to Berths PC-16/17, which underwent anti-aseismic improvement work, at the Port of Kobe. |

| 2014 | TraPac Los Angeles Terminal introduces first automated cargo handling system on the North American West Coast. |

| 2015 | Cutting-edge, fully automated container terminal Rotterdam World Gateway (RWG) opens. Large-size cranes that can handle the world's largest containerships are installed at TICT in the Port of Tokyo. |

| 2016 | On-dock rail installation work is completed at the TraPac Los Angeles Terminal. KICT starts Japan's first three-berth integrated operations by renting all space on Berth PC-15. |

| 2017 | Container barge terminal opens in Bangkok, Thailand. |

| 2018 | Tan Cang Haiphong International Container Terminal (HICT), the first deep-water container terminal in Northern Vietnam, opens |

Owned & Operated LNG FSRUs Are Essential to the LNG Value chain, Facilitating Energy Security, Downstream Gas Distribution, and Grid Balancing

The MOL Group is a leader in providing oil and gas solutions. Through technology and innovation, the group plays essential roles in major oil and gas projects to meet energy demand in an ever-changing global market.

The owned FSRUs we manage work as marine floating terminals delivering rapid "to market LNG solutions" to address critical energy demand. The MOL Group is synonymous with dynamic and innovative leadership in the floating LNG sector, giving our organization a unique ability to meet energy demand with a complete gas delivery solution. At the MOL Group, we provide LNG floating solutions across the entire midstream LNG chain with various FSRU projects already in operation and many more in the works.

Our involvement with FSRUs dates back to 2009. As the co-owner of two SRVs since 2009, and the owner/operator of the world's largest FSRU, the group continually strives to enhance the LNG value chain and deliver reliable LNG solutions. With floating terminals in various locations globally (two in Turkey, one in China, and another in development on the west coast of India*), we are well-positioned to provide a full range of regasification services critical to energy security and flexibility in the LNG supply chain.

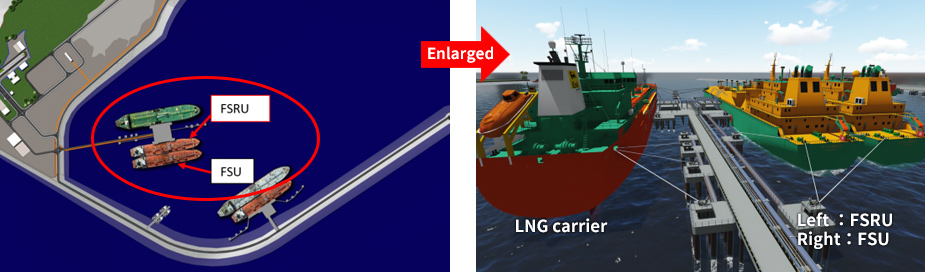

* In our latest LNG marine terminal project, we will operate an LNG receiving facility in Gujarat, India, where the MOL Group will maintain an FSRU and an FSU as core facilities for regasification and storage, while handling the operation and maintenance of a gas receiving facility and its integration to the distribution grid.

FSRU PROJECTS –

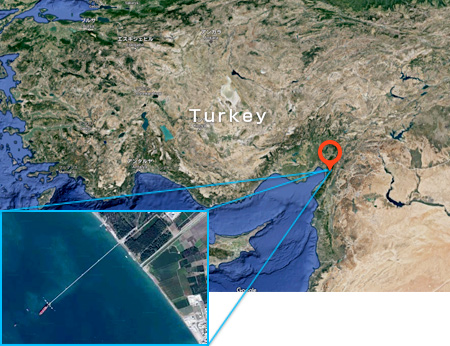

1. MOL Owned-Operated FSRU -TURKEY 2nd FSRU PROJECT -

This is our LNG receiving and regasification terminal project in southern Turkey. The MOL FSRU Challenger, 100% owned by MOL, is engaged in this project. The FSRU will be placed at a newly built jetty in Dortyol to receive imported LNG and regasify it for delivery to users.

2. MOL's FSRU Terminal Company to Handle FSRU/FSU Operation for India Swan Project

In addition to investing in the terminal, MOL will provide FSRU operation and maintenance, supply the FSU and handle operation, maintenance, and technical support for the construction of a newbuilding FSRU for an LNG receiving and regasification terminal project in India.

| Main body | Swan LNG |

|---|---|

| Location of the terminal | Jafrabad, Gujarat State, India |

| Main terminal facilities | 1 FSRU (tank capacity: 180,000m3)、 1 FSU (tank capacity: 135,000m3 -145,000m3), breakwater, jetty mooring, onshore facilities |

| LNG receiving capacity | 5.0 million tons/year |

| Start of operation | Early 2020 |

Other Projects

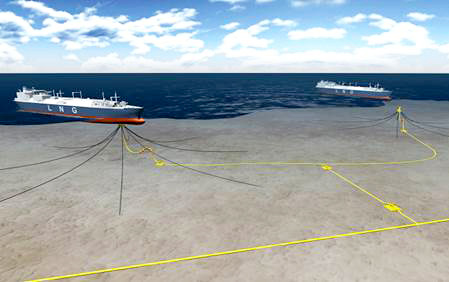

2009 - Neptune Project - SRV will send gas through a submerged turret buoy and undersea pipeline off Boston, Massachusetts, USA.

2013- Tianjin Project - First floating LNG import project in China, bridging import solution with regasification capacity of 21Msm3/d(mega standard cubic metres per day). In the winter of 2017, the FSRU was deployed for temporary transmission to meet emergency demand.

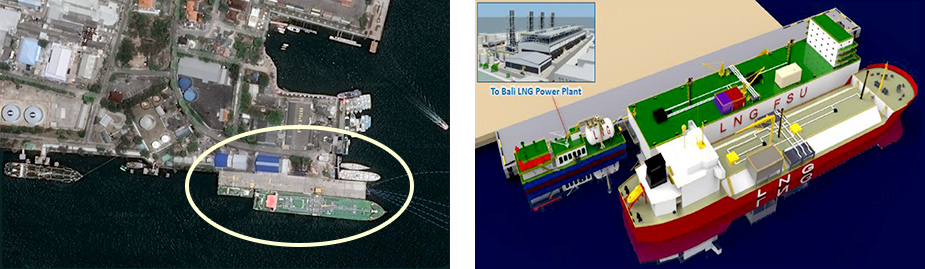

2016- Benoa Indonesia project - Domestic project for 200 MW power plant.

FRU (regasification facility only) and FSU (storage only) are in operation at Benoa port in Indonesia to supply LNG to a 200 MW power plant in Bali. MOL is providing an LNG shuttle vessel.

2016- ETKI FSRU Project in Turkey – First floating LNG import project in Turkey with regasification capacity of 21 Msm3/d. The terminal is located 300 meters offshore in Aliaga, Izmir and designed to accept up to Q-Flex LNGC (217,000m3 capacity). The FSRU was employed in 1Q 2017 for 3 years charter.

MOL Group FPSO Business Contributes to Stable Supply of Crude Oil off Brazil, West Africa

For more than a century, the MOL Group has provided safe, environmentally friendly shipping services.

Through technology and innovations, the MOL Group is playing vital roles in major oil and gas projects to meet the demand for energy in an ever-changing global market. We are committed to continuously developing our floating LNG/oil solutions and retain leadership in niche natural gas and oil production technologies, expanding our LNG regasification footprint, and fostering a corporate culture where safety, environmental excellence, and responsible operating principles are given the highest priority in all our activities.

Our FPSO systems provide competitive floating solutions for the offshore oil gas industry, and oil field development forms a part of the MOL Group's energy portfolio. Oil field development has shifted from onshore to offshore and from shallow to deep waters. With seven FPSO systems (six in Brazil and one in West Africa), the MOL Group and its partners are determined to safely and responsibly unlock energy resources from deep water assets and develop these oil fields in an environment friendly manner.

FPSO Projects

2010 - FPSO Cidade de Angra dos Reis MV22 - Lura field- Spread moored in 2,149 meters of water in the pre-salt region of the Santos Basin, with processing capacity of 100,000 barrels of oil/day and 150 mmscfd of gas.

2014 - FPSO Cidade de Mangaratiba MV24 - Iracema Sul Area - Spread moored in 2,200 meters of water in the pre-salt region of the Santos Basin. Processing capacity of 150,000 barrels of oil/day and 280 mmscfd of gas.

2015 - FPSO Cidade de Itaguaí MV26 - Iracema Norte Area- Spread moored in 2,240 meters of water in the pre-salt region of Lula Norte. Processing capacity of 150,000 barrels of oil/day and 280 mmscfd of gas.

2016 - FPSO Prof. John Evans Atta Mills - Tweneboa, Enyenra and Ntomme (TEN) fields - External Turret moored in 1,500 meters of water in 10 fields off Ghana. Processing capacity of 80,000 barrels of oil/day and 180 mmscfd of gas.

2016 - FPSO Cidade de Caraguatatuba MV27 - Lapa Field- Spread moored in 2,126 meters of water in the pre-salt Lapa field off Brazil. Processing capacity of 100,000 barrels of oil/day and 177 mmscfd of gas.

2018 - FPSO Cidade de Campos dos Goytacazes MV29- Tartaruga Verde and Tartaruga Mestica Fields- To be deployed in a spread moor configuration at Tartaruga Verde and Tartaruga Mestica Fields. Processing capacity of 150,000 barrels of oil/day and 176 mmscfd of gas.

Future Projects -

2021 - FPSO Carioca MV30 - Sépia Field - The FPSO will be deployed at the Sépia field located in the giant pre-salt region of the Santos Basin some 250 kilometers off the coast of Rio de Janeiro, Brazil, at a water depth of approximately 2,200 meters.

The FPSO will have the capacity to process 180,000 barrels of crude oil per day, 212 million standard cubic feet of gas per day, and 240,000 barrels of water injection per day, with storage capacity for 1,400,000 barrels of crude oil.

MOL Group Takes Charge of Maintaining Shirashima National Oil Storage Terminal

Japan is one of the world's major oil-consuming countries, and depends on imports for more than 99% of its supply. A disruption in imports would have a huge impact on Japan's economy. In 1975, after the enactment of the Oil Reserve Law, the nation approved an emergency oil reserve and emergency response system to ensure a stable supply of oil.

Japan is one of the world's major oil-consuming countries, and depends on imports for more than 99% of its supply. A disruption in imports would have a huge impact on Japan's economy. In 1975, after the enactment of the Oil Reserve Law, the nation approved an emergency oil reserve and emergency response system to ensure a stable supply of oil.

Japan has limited space and is prone to earthquakes, making land-based oil storage facilities impractical. These factors led to the creation of the Shirashima National Oil Storage Terminal in 1996. Shirashima is Japan's largest petroleum reserve, on the sea 8km off Kita-Kyushu City. The base features state-of-the-art safety systems to protect the environment, and can store 56 million KL of oil.

The MOL Group has been involved in maintenance work at this facility since its inception.

For the History of the Offshore Business, please go to Offshore Business

Related URL: MOL Group