Bulkships carry resources and tankers carry energy. Here, we have other types of vessels that carry finished products.

This section introduces car carriers that transport automobiles and containerships that carry a wide variety of cargoes such as apparel,

appliances, and other items we use every day.

Leaders in Ocean Transport,

Connecting the World with a Network of Sea Routes

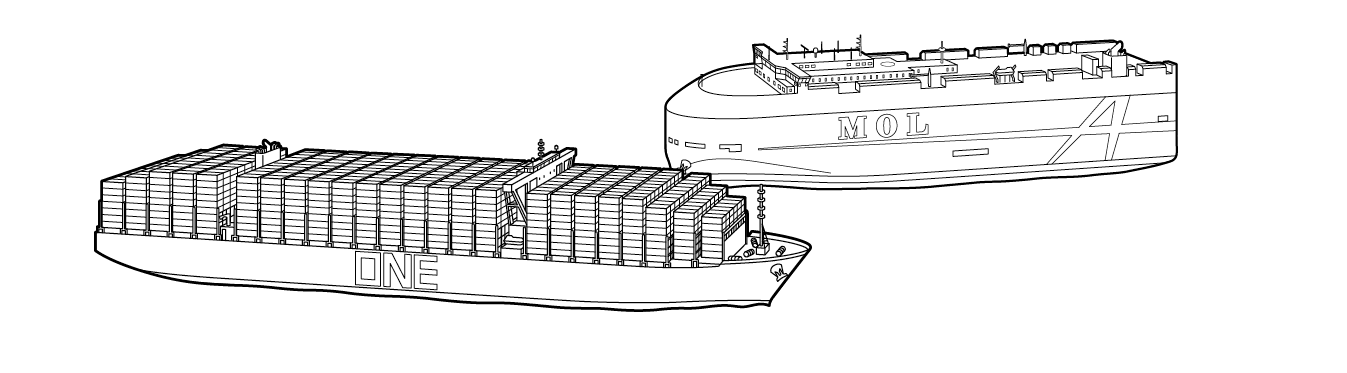

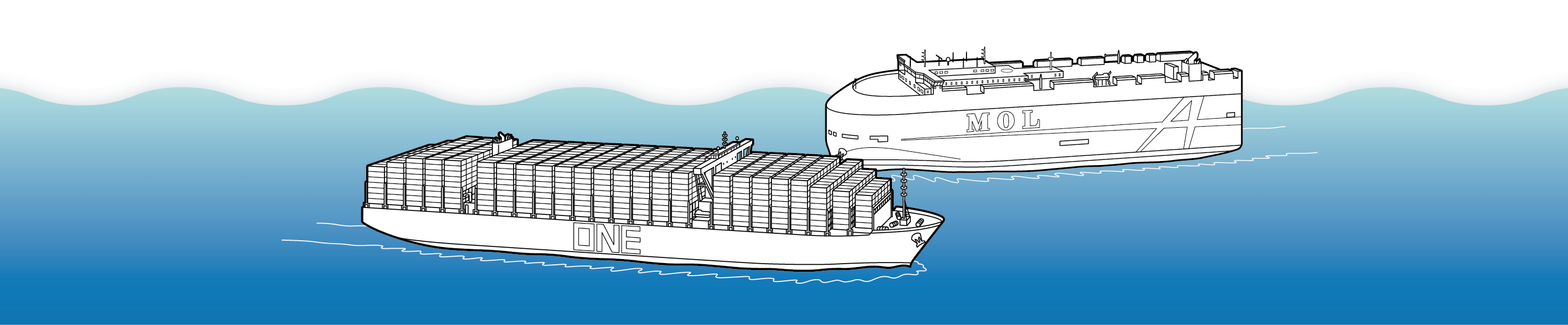

In contrast to bulkships, tankers, and LNG carriers that transport energy resources and raw materials, MOL’s car carriers and containerships carry finished products in large quantities.

Japan’s automobile exports began in earnest in the late 1950s, and currently about 4 million vehicles are exported annually. In response to booming car exports, dedicated vessels called pure car carriers (PCCs) were developed to ensure the safe, efficient transport of completed vehicles (mainly automobiles).

In addition, containerships, which have spurred innovation in global logistics and are sometimes referred to as the greatest human invention of the 20th century, are important vessels that support the foundation of ocean transport. The efficiency of product transport has continued to advance, and today’s largest vessels can carry more than 20,000 containers at one time.

for Efficient Mass Transport of Vehicles

-

![]()

-

Car Carriers

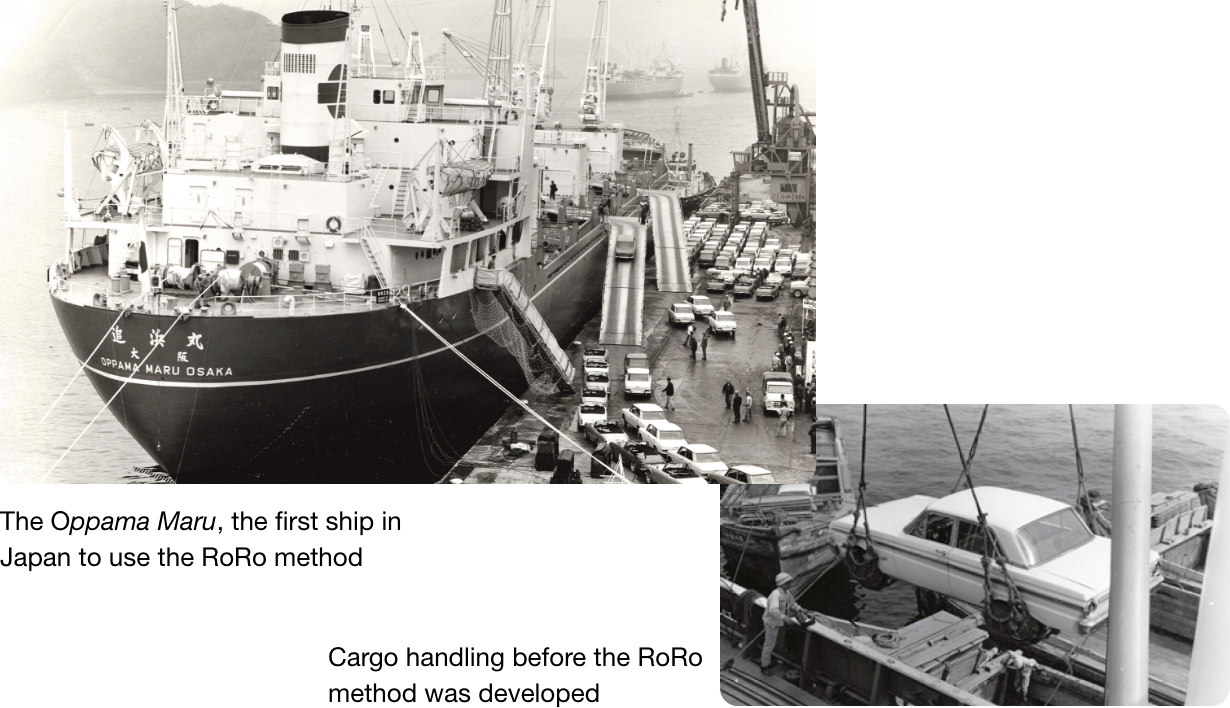

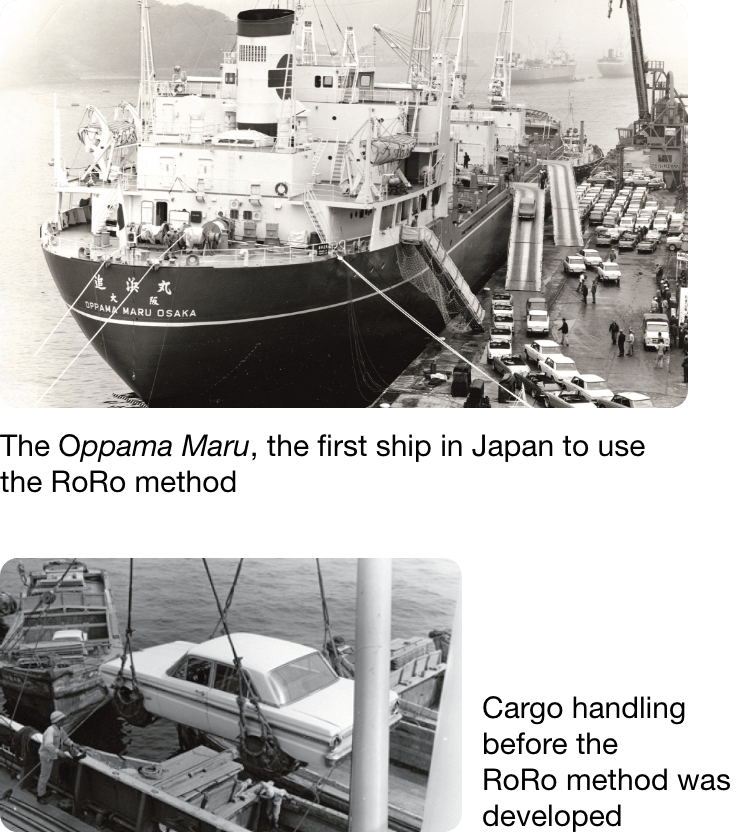

These vessels are called pure car carriers (PCCs) or pure car and truck carriers (PCTCs), and they are designed specifically to transport self-propelled cargoes such as automobiles and construction machinery. In 1965, MOL launched Japan’s first specialized car carrier equipped with loading/unloading equipment, the Oppama Maru.

![]()

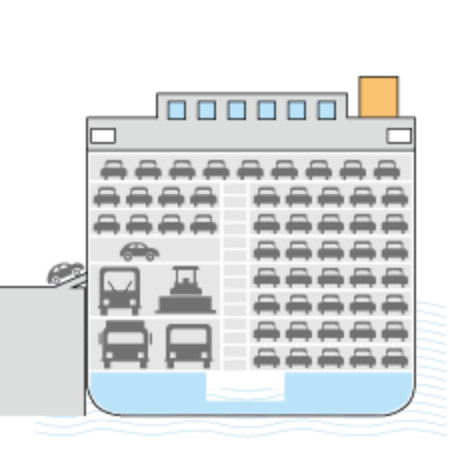

PCCs and PCTCs have a multi-story deck structure, like multi-level parking lots. Because their unique hull shape exposes a large area to the wind, they are more susceptible to “leeway,” in which the vessel is pushed by the wind and proceeds at an angle, than other ships. MOL’s car carriers feature rounded bows with a diagonal cut to reduce crosswinds and improve fuel efficiency, and the sides are stepped over the entire length of the vessel to reduce the effects of crosswinds.

Some of the cargo decks are “liftable decks,” which means their height can be adjusted in accordance with vehicle height, so vessels can load not only passenger cars, but also taller vehicles such as buses, trucks, and even large construction machinery. To maximize loading capacity, the drivers leave just 30cm between the front of one car and the rear of the next, and a mere 10cm from side to side.

In the days of the Oppama Maru, car carriers could hold about 1,200 vehicles, but current PCCs and PCTCs have capacities of up to 8,500 units. Loading capacity is calculated for standard passenger cars measuring 4.125m long and 1.55m wide. MOL’s FLEXIE series vessels, delivered in 2018, have capacities of 6,800 units, and can flexibly accommodate a wide variety of vehicles. They have 14 decks, six of which are height-adjustable, and can load cargo as tall as 5.6m. And the rampway can hold cargo weighing up to 150 tons. These modern vessels can transport virtually any type of vehicle and a range of other self-propelled cargoes as well.

MOL teamed up with automakers on joint research that led to the realization of a completely new idea: the roll-on/roll-off (RoRo) method, in which automobiles are driven on and off the vessel.

with International Standard Containers

-

![]()

-

Containerships

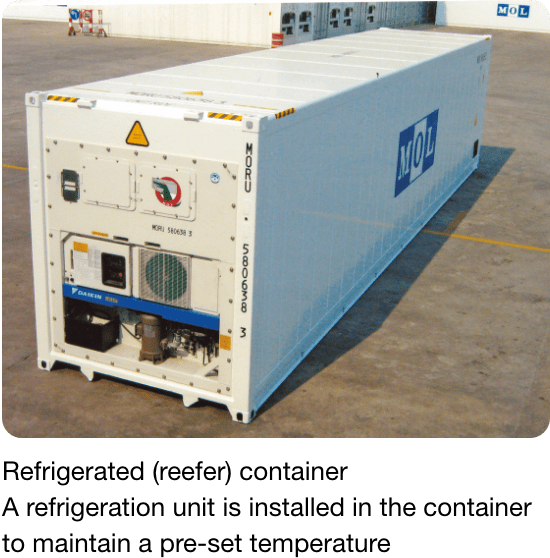

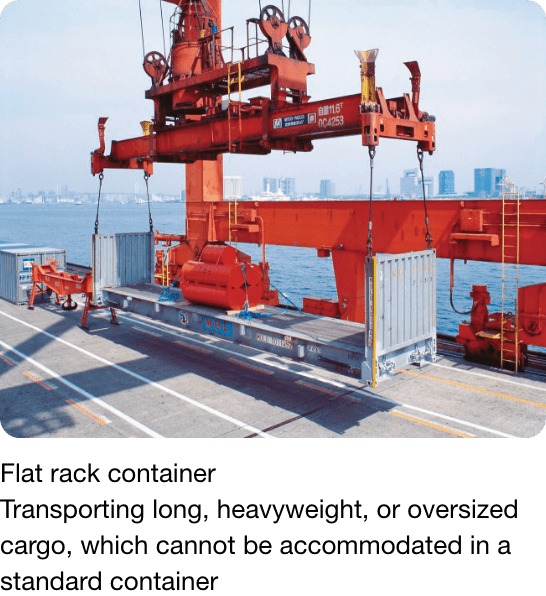

These vessels carry cargoes that are loaded into international standard shipping containers. Shipping routes and schedules are set in advance like bus or train services, and vessels periodically call at predetermined ports. In addition, containerized cargoes can be swiftly and easily reloaded to trucks and rail cars, making it possible to provide integrated door-to-door transport service.

![]()

Containerships call at dedicated terminals that have container loading and unloading facilities and equipment. So generally, these vessels are not equipped with onboard cranes. Vertical rails called “cell guides” are installed in cargo holds to load containers efficiently, and the containers are lashed to keep them in place. “Lashing bridges” serve as scaffolds for lashing operations on deck. In addition, containerships can sail at higher speeds than other ship types to maintain stable calling schedules.

Shipping containers, which were introduced in the 1950s, had a massive impact on the trade and transport of commodities and products, not to mention the development of global supply chains. At the time, ocean cargo transport depended mainly on labor-intensive and inefficient cargo loading processes. In fact, labor costs accounted for the majority of logistics expenses. However, the use of standardized shipping containers has made it possible to transport large quantities of miscellaneous goods safely and inexpensively.

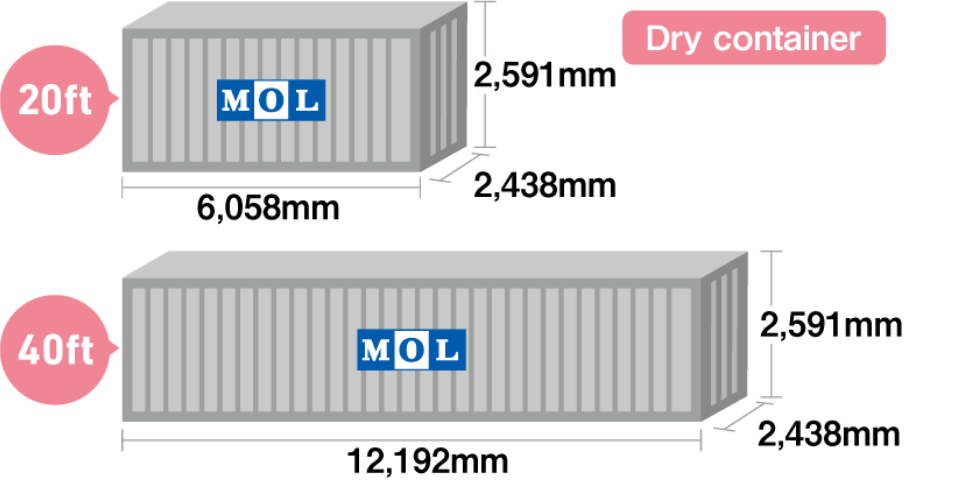

- There are basically two lengths for containers: 20 feet and 40 feet.

- Numbers on the container designate its owners, type, and size.

- Loading capacity and transport records of containerships are expressed in “TEUs,” a term that stands for “Twenty-foot Equivalent Unit.” A 20-foot container is 1 (one) TEU. A 40-foot container is counted as 2 TEUs.

-

![]() ‘FLEXIE’ series car carriers offer the flexibility to transport a wide variety of vehicles

‘FLEXIE’ series car carriers offer the flexibility to transport a wide variety of vehicles -

![]() A car carrier arrives at the terminal where cars are lined up waiting to be unloaded

A car carrier arrives at the terminal where cars are lined up waiting to be unloaded -

![]() Containers, unloaded from the vessel by crane, are placed directly onto chassis

Containers, unloaded from the vessel by crane, are placed directly onto chassis -

![]() Crewmembers on a lashing bridge check loaded containers

Crewmembers on a lashing bridge check loaded containers