- JP

- EN

Responsible Procurement

Policy

The MOL Group established the "MOL Group Basic Procurement Policy" to fulfill our social responsibility as a corporate group that plays a part in our customers' supply chains. With an eye toward contributing to the realization of a sustainable society, we promote fair and equitable procurement activities, in consideration of compliance with laws and regulations covering supply chains, conservation of the environment and natural resources, respect for human rights, and doing our utmost to ensure safety, while gaining the understanding and cooperation of our business partners.

The policy was established in 2012, and revised in 2022, with the approved of the MOL Board of Directors.

- MOL Group Basic Procurement Policy

-

The MOL Group procures products and/or services in accordance with the following basic policy:

- We comply with applicable laws, regulations, and social standards to ensure fair and equitable trade opportunities and procedures based on free competition open to others, both domestic and overseas.

- We strive to reduce the negative impact of our procurement activities by considering environmental and resource conservation.

- We respect basic human rights and conduct procurement in consideration of work environment in accordance with laws and international standards.

- We procure products and/or services, including the delivery or execution of such products and/or services, that meet high safety standards.

We work to build relationships of trust with our business partners so they understand and cooperate with this policy, with the aim of mutual contribution toward the realization of a sustainable society.

Established in March 2012

Revised in March 2022

Suppliers Procurement Guidelines

We believe the cooperation of our business partners is indispensable to enhancing the transparency and sustainability of supply chains, as the MOL Group develops businesses on a global scale. In FY2021, we established the MOL Group Supplier Procurement Guidelines. These cover issues where we seek the understanding and cooperation of our business partners. In the future, we will work to promote the wide adoption of guidelines among our key business partners, and ensure that they understand the intent behind them.

We ask all of our business partners to address the items specified in the guidelines and promote sustainable procurement activities and urge your partners to adopt these standards as well.

Furthermore, to ensure that our trade practices and commercial practices do not hinder our business partners' compliance with the 'MOL Group Basic Procurement Policy/MOL Group Supplier Procurement Guideline,' we will continuously monitor the ordering methods, payment of fees, and transaction/contract details regarding the determination of fees between parent companies and subcontractors. We will actively work to correct trade practices and commercial practices.

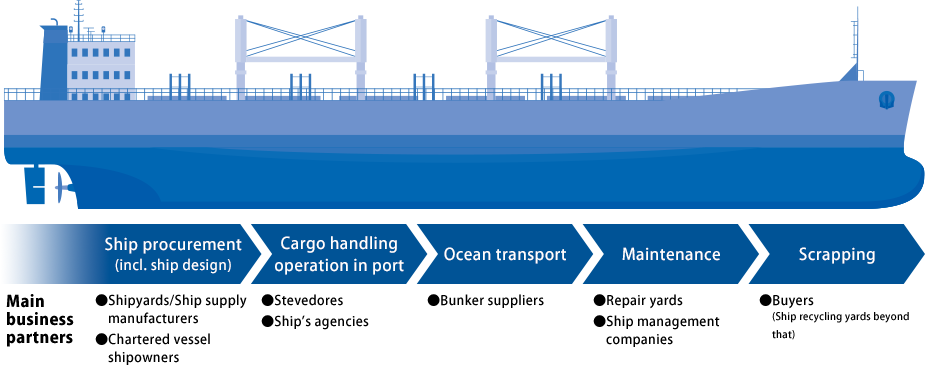

MOL Group value chains

In ocean shipping, the core of our group's business activities, we create value chains with various business partners that span everything from procurement and operation to the eventual scrapping of vessels.

Initiatives

Value Chain Management -MOL Group Partnership Initiatives-

In order to realize sustainable business activities, the MOL Group implements value chain management to identify and reduce sustainability-related risks in the value chain, including environmental, human rights, anti-bribery and other anti-corruption risks.

The understanding and cooperation of our business partners in our value chain is essential for building a sustainable value chain, and we hope to further strengthen our partnership with them through this initiative.

By mutually reinforcing our partners' and our sustainability initiatives, we will strive to enhance the value of value chain as a whole and continue to be an essential part of society in the future.

The implementation of these initiatives will be monitored by the Sustainability Committee, a subordinate under the Executive Committee, and the Board of Directors will be responsible for supervising the implementation.

Basic processes of value chain management

With the aim of ensuring compliance with the MOL Group Supplier Procurement Guidelines, we will introduce and promote the guidelines to our business partners to help them understand the purpose of these initiatives and we will also monitor the status of their initiatives by conducting written surveys covering seven major areas such as the environment, human rights and anti-corruption, including bribery, and detailed interviews and on-site inspections as necessary, taking into account country, sector and commodity risks. As necessary, we will provide summary results of the surveys, overall trends, best practices of other companies, and guidance on how to proceed with future initiatives as reference information. If the survey identifies serious issues, we work together with business partners on future countermeasures in cooperation with experts and NGOs, and continue to provide ongoing support.

Basic processes of value chain management

"MOL Group Partnership Initiatives" (produced in FY2021)

Records in Value Chain Management Initiatives

- Human Rights Policy, Dissemination of MOL Group Supplier Procurement Guidelines

- Implementation of Dialogue through Hearings and Surveys

FY2022 (Some major chartered vessel shipowners)

FY2023-2024 (68 major chartered vessel shipowners, 17 Major shipyards) - Provision of Reference Information

Introduction of Human Rights Due Diligence Processes and Remediation Mechanisms

Provision of E-learning Materials on the Importance of Human Rights in Business

Provision of Overall Trends and Best Practices of Other Companies Regarding ESG, etc.

Initiatives to Improve Internal Understanding

We hold briefings and workshops on value chain management for employees who work closely with our suppliers. The objective is to deepen understanding of the significance of this initiative, the concerns of external stakeholders, and the MOL Group Supplier Procurement Guidelines.

Other Initiatives

Initiatives for shipbuilding

Ship procurement is a key element of MOL Group business activities.

When we order the construction of a ship, we not only request that the shipyard, a supplier, follow MOL Safety Standards Specifications, which specify our safety and environmental quality standards, but also ask them to address concerns regarding environmental measures, safe working conditions, and so on in the shipyard. We also strive to improve the quality of our ships by assigning shipbuilding superintendents from our group companies to the shipyard, where they are jointly involved in the development and introduction of low environmental impact vessels. This is one way that we work with our business partners toward achieving a sustainable society.

Initiatives for chartered vessel shipowners

The MOL Group charters some vessels that are essential to its business from shipowners. We apply MOL Safety Standard Specifications not only to our owned vessels, but also chartered ships (not including those on short-term charters), striving to ensure high fleet-wide standards of quality and safety. In addition, with shipowners, we proactively share safety awareness, exchange information and opinions to improve safety/quality through visits to ships, plus meetings and periodic liaison group activities with shipowners. And in response to the grounding//oil spill incident involving the MOL-chartered bulk carrier Wakashio off the coast of Mauritius in 2020, we recognized anew that we have a profound social responsibility to prevent the reoccurrence of such an incident, even with a chartered vessel, and we have stepped up our efforts to achieve the world's highest level of safety and quality, working closely with shipowners.

Initiatives for ship recycling

Safe and environmentally appropriate ship recycling

Recycled steel from ship recycling supports the demand for steel in various countries and regions, and demand is also increasing important in response to growing environmental awareness and reduce the burden on the environment impact. Recycled steel from vessels is also highly valued for its material quality, making it a precious resource. On the other hand, issues related to the management and disposal of hazardous substances during dismantling, environmental impact, and worker health and safety management have been recognized internationally. In response to these challenges, in 2009, the Hong Kong International Convention for the safe and environmentally sound recycling of ships ("Hong Kong Ship Recycling Convention") was adopted at the International Maritime Organization (IMO) with the objective of addressing issues related to ship recycling and promote safe and environmentally sound practices. This convention entered into force in June 2025. MOL is committed not only complying with this convention, but also to fulfilling its responsibilities as the owner and seller of ships to be recycled. In cooperation with ship recycling yards, we conduct ongoing on-site inspections and dialogues while giving due consideration to the environment, human rights, safety, quality, anti-bribery, and other anti-corruption measures, engaging to Value Chain Management.

Superior Ship Recycling Standards (SSS)

In line with the above background, the MOL group has formulated its own ship recycling yard selection criteria, the "Superior Shiprecycling Standards" (hereinafter referred to as "SSS"), in FY2023 to promote sustainable ship recycling. This standard is regularly reviewed and updated.

Overview of the screening process:

In screening each ship recycling yard, we established a number of criteria that incorporate a variety of items, such as certification status from Nippon Kaiji Kyokai (ClassNK) regarding the Hong Kong Ship Recycling Convention, as well as compliance with regulations, laws, and international treaties, encompassing concerns for the environment, human rights, safety and quality, and prevention of corruption and bribery, as stipulated in the "MOL Group Supplier Procurement Guidelines." Based on these criteria, we select yards after risk assessment (screening) through a written survey and on-site inspection. In the selection process, we also consider advanced environmental initiatives and activities that contribute to the local community, and have established a system to prioritize the selection of yards with high ESG performance.

Operation after screening and selection:

We will confirm that the selected yards are being operated in accordance with the screening criteria even after selection through periodic monitoring such as written surveys and on-site inspections. At that time, yards that do not meet the criteria by the time of the regular year-end review will be excluded from the selection process. We will also encourage yards that are not selected to improve their facilities and operations through feedback on the content of the screening process, thereby continuing the yard selection activities.

During the vessel dismantling period, we or a third party will be commissioned to conduct on-site monitoring to confirm the status of actual operations.

Records of yard screening and selection:

Since FY2022, we have been investigating recycling yards certified under the Ship Recycling Convention by the Nippon Kaiji Kyokai (ClassNK), which is a core criterion for SSS selection. We conducted on-site surveys of all relevant recycling yards in major recycling locations such as Bangladesh, India, and Turkey (excluding those that did not meet other essential criteria during the preliminary survey stage).

We select recycling yards that strive to mitigate risks at a high level from various perspectives, including working environment and conditions, environmental conservation, equipment and its maintenance and operation, regulatory compliance and management, and human rights and so on.

In March 2025, we updated the selection of recycling yards. For some yards, we decided not to continue their selection due to non-compliance with SSS standards discovered after the previous selection. Additionally, new yards that met the criteria were added to the selection.

Through the selection update survey, we identified issues such as wage regulations and operations, employee dormitories, and inappropriate operations and equipment deficiencies. We provided feedback to encourage improvements. If improvements were not confirmed, we decided not to continue their selection. We then prepared for selection updates by monitoring progress through subsequent dialogue and follow-up surveys, aiming for continuous risk reduction in collaboration with the recycling yards.

Surveys・Screened Yards

| FY22 | FY23 | FY24 | |||

|---|---|---|---|---|---|

| survey | screened | survey | screened | survey* | screened |

| 37 | 13 | 60 | 20 | 44 | 16 |

* Periodic and initial surveys. A total of 63 investigations were carried out, including multiple investigations into the same yard.

Face-to-face direct dialogue with employees in ship recycling yard:

In the second half of fiscal year 2024, we conducted direct dialogues at some SSS screened yards in India and Bangladesh for the purpose of assessing human rights risk.

This dialogue assessment involved both the management and employees of the yards respectively and were conducted in collaboration with third-party expert specializing in business and human rights, ensuring transparency and objectivity throughout the process.

Worker's interviewees for the dialogue sessions were randomly selected by interviewer side from employee lists. The sessions were conducted in 7 to 8 groups organized by job type, position and reporting lines. To encourage open and honest discussion, the dialogues were held in a separate room without any potential pressure or surveillance, facilitated through an interpreter in local languages, Hindi and Bengali.

The interviews focused on key areas related to workers' rights, including working hours, wages, employment status, working conditions, health and safety, discrimination and harassment, freedom of association, and access to grievance mechanisms.

Interview

MOL's Records of yard screening (Since 2019)

| Year | Ship name | Yard | Plot # | LDT | Year of Built |

Scope | |

|---|---|---|---|---|---|---|---|

| Before SSS | 2019 | Green Garnet | NBM Iron and Steel Trading Pvt.Ltd | 61(24G) | 9,186 | 1996 | Mitsui O.S.K. Lines, Ltd. |

| 2019 | Rakiura Maru | Leela Green Ship Recycling Pvt.Ltd | 35 | 8,368 | 1996 | ||

| 2019 | Meridian | Triveni Ship Breakers LLP | 23 | 9,142 | 1996 | ||

| 2020 | Universal Green | Baijnath Melaram | 13 | 10,631 | 2002 | ||

| 2020 | Tachibana | Diamond Industries | 84 | 19,098 | 2000 | ||

| 2020 | Cougar Ace | Anupama Steel limited | 15 | 13,551 | 1993 | ||

| 2021 | Senshu Maru | Sachdeva Steel Products (SB) Ltd | 65(24L) | 29,819 | 1984 | ||

| After SSS | 2023 | Siam Ocean | PHP Ship Breaking and Recycling Industries Ltd | - | 7,996 | 1995 | |

| 2024 | SURYA AKI | PHP Ship Breaking and Recycling Industries Ltd | - | 8,168 | 1996 |

Dismantling work at our selected ship recycling yard

Right: Dismantling operations in cargo hold

Middle: Gas detection in a tank before work

Right: Renewal and repainting of escape routes

- Sustainability TOP

- Message from the Chief Sustainability Officer

- Sustainability

Management - Value Creation

Stories - Safety & Value

- Environment

- Human & Community

- Innovation

- Governance

- Stakeholder

Engagement - Sustainable Finance

- Sustainability Data

- ESG Disclosure

Guideline Indexes - External Recognition

- Library