- JP

- EN

Pre-emptive Management of Risk and Dangers

Working Closely with Shipyards

Vessels used in our group's business are procured from domestic and overseas shipyards. We assign an appropriate number of resident supervisors with technical expertise to each project to supervise construction, to ensure a safe construction process and a top-quality vessel that precisely meets our needs.

Shipbuilding supervisors have the following three duties at the shipyard:

- Quality Management

Quality management verifies that shipyards reliably meet required specifications that contribute to safe operation, rules for each ship type, and other standards. - Process control

We stay on top of day-to-day management to avoid situations that may affect the delivery schedule and allow us to take swift action in case of an emergency. - Health, Safety and Environment (HSE) management

Before the start of construction, we check the differences between the safety guidelines of each shipyard and the "Health Safety Environment (HSE) Manual" prepared by the MOL Group, and share all the details in advance with the superintendents we will dispatch to the construction site. We strive to improve occupational health and safety at shipyards by pointing out potential violations of laws and regulations and urging shipyards to make improvements, and by introducing outstanding examples from other companies.

They work on-site at the shipyard for one to two years from the initial stage (about a month after steel cutting) to the completion of the vessel.

Accident Response Drills

We continuously conduct training to ensure appropriate responses in the event of an emergency or trouble.

On board, we regularly conduct emergency response drills for fire, flooding, and other situations. Furthermore, MOL Group companies that operate ferries and cruise ships conduct regular emergency response drills, including evacuation guidance, as they put the highest priority on ensuring customer safety in an emergency.

On land, once a year at the head office, the president and other relevant officers, relevant departments, and ship management companies jointly conduct emergency response drills in anticipation of serious marine accidents. The purpose of this training is to raise safety awareness of MOL as a whole by simulating a serious marine accident, and to confirm that the necessary response and information transfer can be conducted accurately and smoothly in the event of a serious marine accident.

By sharing and improving the know-how accumulated through this training and newly discovered issues, we will further strengthen our emergency response system for emergencies.

Initiatives Against Geopolitical Risks and Natural Disaster Risks

Pirates and robberies

In the Gulf of Guinea, off the coast of the Gulf of Aden and Somalia, and in the Straits of Singapore, where there is a risk of piracy occurring, we are strengthening surveillance on ships by increasing the number of lookouts using radar and night vision, and by increasing the number of lookouts.

To ward off pirate attacks, the ship is equipped with razor wire and crew members wear bulletproof vests and helmets. In the event that there is a high risk of being boarded by pirates, the crew will be evacuated to an evacuation area called the Citadel to prevent any harm to the crews until the rescue of warships arrives.

On land, our Safe Operation Support Center (hereinafter SOSC) shares information on piracy and other incidents with vessels navigating in dangerous waters to raise awareness. In addition, a monitoring system is used 24 hours a day to check whether vessels are implementing prescribed measures such as speed increases in accordance with the navigation guidelines established by our company.

Terrorism

It is very difficult to predict terrorist acts, but when we receive information that an incident has occurred, the SOSC disseminates the information to vessels operating in the vicinity and related parties without delay to alert them.

In particular, the situation remains tense in the Middle East, including the Persian Gulf, the Gulf of Oman, the Red Sea, and the Arabian Sea, with attacks on vessels. When entering such high-risk waters, we take all necessary security measures, such as increasing the number of lookouts, rechecking fire extinguishing equipment in preparation for fires, and avoiding navigation in coastal areas.

In addition, on land, we understand the status of vessels scheduled to enter the Middle East, and continuously collect security information on the situation in the Middle East and incidents of attacks from industry organizations, security investigation companies, and vessels navigating in the vicinity so that we can take prompt action when we receive security information that is a concern for safe navigation.

Conflict areas

For countries where there are security concerns, such as Libya where political unrest continues, we obtain risk assessments from security survey companies when calling ports or navigating their coastal waters. We have established our own necessary navigation guidelines, including the setting of no-navigable areas to avoid entry into areas of particularly high risk. In addition, on land, the SOSC constantly monitors the movements of vessels based on these navigation guidelines.

Natural disaster risks

Typhoons and other natural phenomena such as stormy weather can sometimes cause serious damage to vessels.

In particular, earthquakes and tsunamis occur suddenly and are difficult to predict.

It is therefore very important to collect all available information in a timely manner and to conduct risk management for vessel navigation, an essential element for safe operation.

In order to ensure the safety of crew and cargo from natural disaster risks, MOL has established the Safety Operation Support Center (SOSC) with two staff members on duty at all times, including one who has experience as a captain, to monitor vessel movements 24 hours a day and the forecast information for weather and sea conditions.

In the event of an accident or trouble on a vessel caused by a natural disaster, the Center provides necessary information to the vessel and related departments on shore and supports the captain and operators to help them make the appropriate decisions.

ICT supporting safe operation

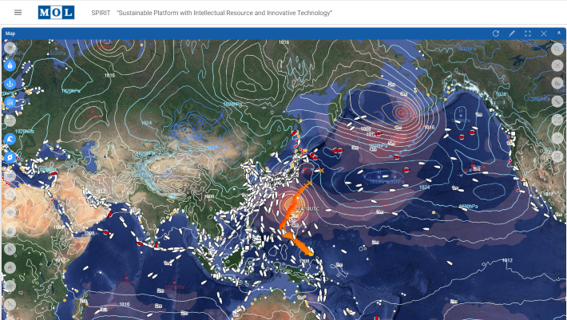

The Safety Operation Supporting Center (SOSC) monitors and supports operating vessels based on information obtained from various systems and sources. This section introduces the ship motion monitoring system and the stranding risk monitoring system, which are representative of these systems.

vessel movement monitoring system

SPIRIT (Sustainable Platform with Intellectual Resource and Innovative Technology), released in January 2021, is a system capable of monitoring where our company vessels are around the world and in what kind of weather and sea conditions.

In addition to monitoring at SOSC, the system is also used by operators and company personnel to support the vessel.

This system can monitor not only weather and sea conditions, but also pirates, exercises, high risk areas (HRA), and other information while comprehensively assessing risks. Since April 2022, the vessel's navigation plan has been incorporated into the system to further strengthen support.

grounding risk monitoring system

Grounding risk monitoring system, that combines a number of data sources, such as ship position, water depth, and chart information, to alert SOSC operators when a vessel is judged to be entering an area with a high risk of grounding.

SOSC, which monitors vessels in operation 24 hours a day, 365 days a year, constantly monitors the system and initiates the system when an alert is issued.

Ship Inspections

Ship Inspection Activities Targeting All Operated Vessels

MOL conducts periodic ship inspections, based on our unique safety standards, targeting all MOL Group-operated vessels, regardless of whether they are owned or chartered.

These inspections verify that the vessels are properly maintained and can operate safely and reduce the risks that may impede with the safe operation of the vessel.

With chartered vessels, we communicate closely with the shipowners and assigned ship management companies, to make sure they have a full understanding of the safety standards we require. We also cooperate with them to pursue safety measures while building mutually trusting relationships.

Thorough Investigation by Highly Skilled Ship Inspectors

A team of two ship inspectors, who have a thorough knowledge of MOL's safety standards, personally visit ships and conduct detailed investigations based on our own checklist, such as the vessels' operational and maintenance status of the vessel, ship management status, and so on.

Even when it is difficult to visit vessels due to various circumstances, the remote vessel inspection (Examine photographs or video images, Documents, Questionnaires, etc. from shipowners and ship management companies) is continued.

If they spot an unsafe or non-conforming condition, they make sure the vessel and its ship management company take appropriate corrective measures so the ship meets MOL's strict safety standards.

Their completed report, which covers the entire inspection and is illustrated with photographs, is circulated among relevant divisions including the responsible business division. Thus, the quality of the vessel is confirmed. In the case of chartered vessels, the shipowner receives any corrective guidance through the business division. This consistent, professional approach ensures the safety of both owned and chartered ships.

- Sustainability TOP

- Message from the Chief Sustainability Officer

- Sustainability

Management - Value Creation

Stories - Safety & Value

- Environment

- Human & Community

- Innovation

- Governance

- Stakeholder

Engagement - Sustainable Finance

- Sustainability Data

- ESG Disclosure

Guideline Indexes - External Recognition

- Library