- JP

- EN

MOL Completes Concept for Series of New-Generation Vessels

-First Announcement: ISHIN-I Car Carrier-

September 10, 2009

TOKYO - Mitsui O.S.K. Lines, Ltd. (MOL, President: Akimitsu Ashida) today announced that the company has formed the concept for its next-generation vessels, which will be a technically practical in the near future, by building on and refining technologies it has already developed and adopted.

The first is a next-generation, environment-friendly car carrier. MOL continues to work on concepts for other next-generation vessels such as ferries, bulkships, tankers, and containerships.

The company will continue working to stay in the vanguard of technological developments in the global ocean shipping industry.

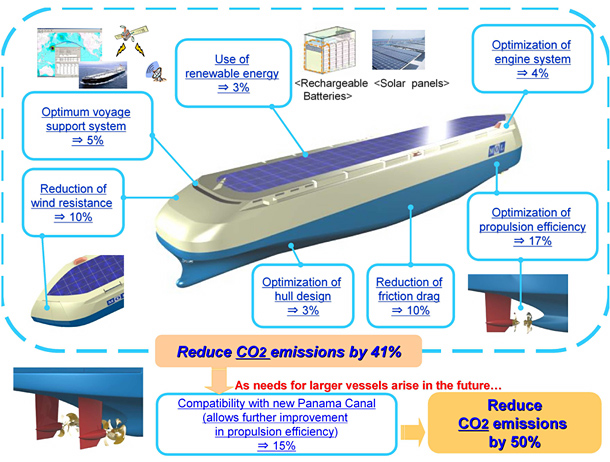

MOL named the first concept: Car Carrier "ISHIN-I (ishin one)," which stands for "Innovations in Sustainability backed by Historically proven, INtegrated technologies." The features are as follows:

ISHIN-I two main features

- (1) While in port, and during loading and unloading: Achieve zero CO2 emissions

Further develops the use of renewable energy for conventional car carriers. Realizes zero emission goal by adopting large-capacity solar-power panels and rechargeable batteries. - (2) Under way: Reduce CO2 emissions by 50% (Note)

Adopts multiple new technologies to greatly reduce the vessel's burden on the environment.

- Note:

- The ship achieves a 41% reduction, in comparison (per unit) to conventional vessels (PCTC with a capacity of 6,400 standard passenger cars). When needs for larger vessels arise in the future, CO2 emissions can be reduced by 50% on that assumption..

* Special Web site is open now

The site offers a detailed look at "ISHIN-I" and the history of MOL's technological innovation.

"ISHIN - History holds the key to the future"

URL: http://www.mol.co.jp/ishin/ *Japanese only

Concept

Main technologies realize two main features

- Use of renewable energy

Wider use of the solar panels partly adopted on the car carriers Euphony Ace and Swift Ace, on all areas of the upper deck on both vessels.

Achieve zero emissions while in port and during loading and unloading by installing large-capacity rechargeable batteries (lithium ion) and combining them with an electric propulsion system. - Optimization of propulsion efficiency

- (1) Contra-rotating propeller drive system

Combine a diesel engine with an electric propulsion system, and place a pair of propellers facing each other at the stern. The propellers share the burden of powering the ship and spin in opposite directions, allowing the rear propeller to absorb the rotation energy of the front propeller. As a result, the system greatly increases efficiency. - (2) Advanced Propeller Boss Cap Fins (PBCF)

This MOL-developed energy-saving device has been adopted on more than 1,700 vessels all over the world. The most advanced model will be installed on the ISHIN-I vessels.

- (1) Contra-rotating propeller drive system

- Advanced wind resistance reducing design

The design was developed by MOL, and the hull shape has been further refined, reducing wind pressure from the bow and sides. The shape of the stern also smoothes the flow of the wind. - Reduction of friction drag

Next-generation vessels will use ultra-low friction ship bottom paint. By trapping water on the coated surface, this paint eliminates friction drag caused by minute patterned indentations formed on conventionally painted surfaces. - Optimum voyage support system

This system relies on the latest marine weather information while monitoring voyage conditions, and searches for the shortest, most fuel-efficient routes while taking into account the differences in various types and hull forms of ships. - Optimization of engine system

Fuel supply to the engine is electronically controlled, and the vessel operates with the optimum fuel supply. Thermal energy conventionally lost with exhaust gas will be efficiently recovered for reuse. - Optimization of hull design

Improve the hull form, in pursuit of further improvements in fuel efficiency. - Larger hull compatible with new Panama Canal

When needs for larger vessels arise, adoption of twin-shaft propellers will allow greater improvement in propulsion performance and fuel efficiency.

This will reduce CO2 emissions per unit transported by up to by 50%, compared to current vessels.