- JP

- EN

Introducing the MOL COILPORTER®, a Differentiated Product for NVOCC Business

- Next-generation Cradle in Steel Coil Container Transport -

April 22, 2020

TOKYO-Mitsui O.S.K. Lines, Ltd. (MOL; President & CEO: Junichiro Ikeda) today announced the joint development of the MOL COILPORTER®-an innovative new way to secure steel coils during container transport-along with MOL Techno-Trade, Ltd. (MOL Tech; President: Hirokazu Hatta; Headquarters: Chuo-ku, Tokyo).

[Video of MOL COILPORTER®]

Please refer to MOL's official YouTube channel for details on the MOL COILPORTER®.

(https://youtu.be/aIUeN6wEljQ)

[Outline of MOL COILPORTER®]

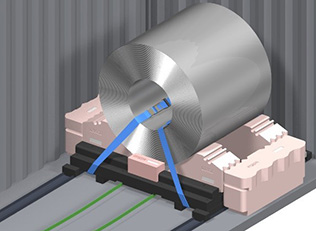

The MOL COILPORTER® is the new cradle used to lash steel coils, an essential material for automobile manufacturing and other industries, to ensure safer containerized transport. Mitsui O.S.K. Kinkai, Ltd. (President: Kenichi Nagata; Headquarters: Minato-ku, Tokyo), which offers transport service for steel materials, Utoc Corporation (President: Masahiro Tanabe; Headquarters: Yokohama-shi, Kanagawa Prefecture), and MOL Logistics (Japan) Co., Ltd. (President: Shuhei Togo; Headquarters: Chiyoda-ku, Tokyo) shared customers' requests with the development team, and to creative approaches to address every detail during the development of the MOL COILPORTER®.

The MOL COILPORTER® trademark has been registered in major countries. And it is already patented in Japan (Patent No. 665025), with several other patents pending (Note 1).

Differences from the conventional lashing are as follows.

- Conventional lashing

-

Assembly/Loading

- About 1 hour by two skilled carpenters (measurement/cutting/carpentry).

- Manually carry and construct with square timbers weighing from 150-200kg.

- Special equipment is required to load into the inner depths of the container.

Disassembly/Unloading

- Requires time-consuming dismantling work such as removal of nails from the lashing material.

- Special equipment is required to unload the coils from deep inside the container.

Resiliency

- Square timbers are in direct contact with coils, subjecting the cargo to risk of damage.

Environmental impact

- Timbers are discarded after dismantled at the unloading operation.

- MOL COILPORTER®

-

Assembly/Loading

- About 3 minutes per cradle even with inexperienced workers.

- Maximum weight of Eperan® (Note 2) is about 3kg/part.

- The cargo can be pushed into the container for loading, and no special equipment is required.

Disassembly/Unloading

- Easy to dismantle thanks to assembly kit.

- The cargo can be pulled out for unloading, and no special equipment is required.

Resiliency

- High resiliency reduces risk of cargo damage.

Environmental impact

- Reusable and recyclable, ensuring more effective use of resources.

[Future Endeavors]

The MOL Group is striving to expand its NVOCC business under the group's unified brand MOL Worldwide Logistics (MWL). MOL Logistics engages in sales under MWL in Japan. To meet customer demand, starting in Japan, MOL Logistics will commence service using the MOL COILPORTER® as a differentiated product in May 2020 as part of its door-to-door NVOCC service.

In addition, the MOL COILPORTER® has acquired the approval (Note 3) of Ocean Network Express Pte. Ltd. (ONE; MOL's investment ratio: 31%) for comprehensive transportation services, based on trial shipments with ONE.

MOL will offer new value in containerized steel coil transport through MOL COILPORTER® and continually develops logistics products that offer stress-free services to customers.

(Note 1)

The claims of JP Patent No. 2017-230685/ 2019-018608/2019-031874/2020-008416/2020-052603

(Note 2)

Registered trademark of Kaneka Corporation. Foamed polyethylene developed by Kaneka. The material has excellent cushioning properties and resiliency and is lightweight.

(Note 3)

The approval for comprehensive transportation services is on the assumption of transport standards independently established by ONE.