- JP

- EN

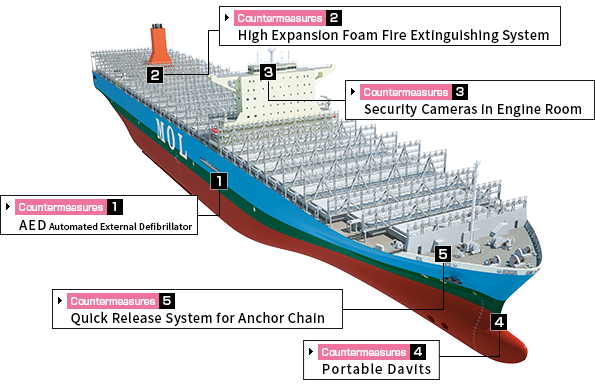

Safety Infrastructure Centered on Technology

MOL Safety Standard Specifications, MOL Design Practices

In order to effectively maintain the safety of MOL operated vessels, MOL formulated the first edition of the "MOL Safety Standard Specifications" in the aftermath of the serious marine incidents that took place in 2006. Since then, the specifications have been revised and applied to MOL operated vessels to ensure the prevention of serious incidents such as collisions and groundings, fires, sinking, loss of hull stability, oil spills and others. Incidents such as these can cause environmental pollution which can have a huge impact on both society at large and the group's profitability, not to mention the loss of trust from customers and other stakeholders.

"MOL Design Practices" systematically compiles knowledge and expertise gained through many years of experience in ship operation. This includes countermeasures for issues such as inferior quality oil, which inhibits ship operation, effective maintenance procedures, and policies and practices that contribute to life saving, security, and environmental protection. These are based on extensive technical and economic analysis.

Some of these countermeasures are as follows. (Click on Countermeasures to see the details.)

- Countermeasures 1: AED-Automated External Defibrillator

- Just in case a crewmember suffers cardiac arrest, one of his or her shipmates can use the AED to administer an electric shock to return the heartbeat to normal, often a life-saving procedure.

- Countermeasures 2: High Expansion Foam Fire Extinguishing System

- In the past, engine rooms were filled with CO2 gas to fully extinguish fires, but if there are any crewmembers on the scene, they may not be able to exit quickly enough and run the risk of oxygen deprivation. Or air could be pumped back into the engine room if the air vent is not closed properly, and the fire will not be extinguished as quickly. To eliminate such risks, MOL introduced the foam extinguisher system that fills the engine room with a massive amount of foam to put out fires.

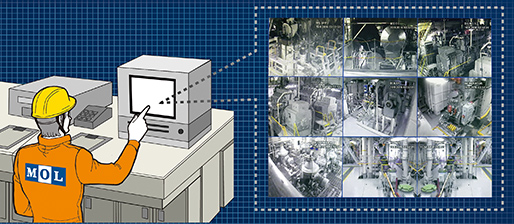

- Countermeasures 3: Security Cameras in Engine Room

- Security cameras in the engine room are set to monitor the equipment that supplies the main engine and generator with fuel. They are also placed along the evacuation route from the engine room. The cameras help us accurately assess the situation when a fire occurs, secure the safety of crewmembers during fire extinguishing operations and evacuation, and review the security camera footage after the fact.

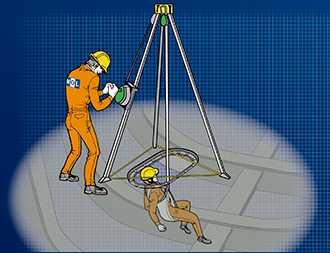

- Countermeasures 4: Portable Davits

- We assume that crewmembers may not able to move during operations in closed zones such as ballast tanks. Use of portable davits allows for speedy and reliable rescue.

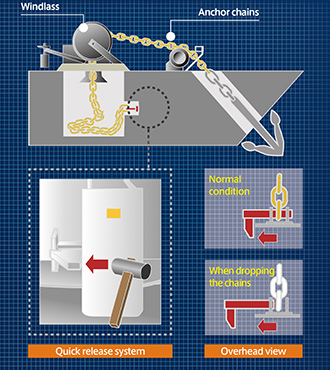

- Countermeasures 5: Quick Release System for Anchor Chain

- During the incident that led to the grounding and sinking of an iron ore carrier in 2006, the anchor chain could not be released quickly. This was one of the factors that greatly worsened the situation. Based on this bitter experience, we introduced a quick release system for our vessels' anchor chains. In an emergency, if the anchor cannot be winched aboard by the windlass, or when there is no time to winch the anchor and anchor chain aboard, the quick release system lets the vessel drop the anchor chain by quickly releasing the connection between the anchor chain and the hull to free the vessel, ensuring the safety of the ship and saving lives.

Ship Monitoring System

Engine Operation Status Monitoring

MOL is utilizing a next-generation ship management support system called FOCUS (Fleet Optimal Control Unified System), which leverages the Fleet Transfer installed on MOL operating vessels.

MOL is using this system to focus on monitoring engine operating conditions and immediately notifying the ship-management company and the ship if found any abnormalities, thereby enabling us to identify problems promptly and minimize downtime.

- Sustainability TOP

- Message from the Chief Sustainability Officer

- Sustainability

Management - Value Creation

Stories - Safety & Value

- Environment

- Human & Community

- Innovation

- Governance

- Stakeholder

Engagement - Sustainable Finance

- Sustainability Data

- ESG Disclosure

Guideline Indexes - External Recognition

- Library