- JP

- EN

MOL Adopts 'Hawk Eye' Transfer Crane Safety Monitoring System

- Contributing to safer, more reliable loading/unloading

March 03, 2009

TOKYO - Mitsui O.S.K. Lines, Ltd. (MOL; President: Akimitsu Ashida) today announced the adoption of the Hawk Eye crane safety monitoring system, which uses a microwave*1 sensor, on the transfer cranes at the Tokyo International Container Terminal*2. The system was developed by MOL subsidiary Nihon Engineering Co., Ltd.*3

The system will enhance safety and reliability of loading/unloading operations, and help prevent accidents at the terminal.

This is the first such monitoring system in the world to use a microwave sensor; and the developers have applied for a patent on the technology.

MOL plans to introduce the Hawk Eye system at its operated container terminals in succession, as part of ongoing group-wide efforts to ensure the safety and reliability of container loading/unloading operations.

*1 Microwaves are radio waves categorized by specific wavelengths. They tend to travel in a straight line in open areas, because of their short wavelength, and will reflect off of any metal obstacle in their path.

*2 Tokyo International Container Terminal (TICT): MOL-operated container terminal in Ohi Pier, Tokyo. During development of this system, TICT conducted the proving tests with the cooperation of the International Container Terminal Co., Ltd. (MOL's wholly owned subsidiary), which manages and operates the terminals, and the Terminal Engineering Co., Ltd., which provides maintenance and management services for loading/unloading equipment, including transfer cranes.

*3 Nihon Engineering Co., Ltd. is an MOL subsidiary that provides inspection and maintenance services for refrigerated shipping containers. The company developed the Hawk Eye system in cooperation with the New Japan Radio Co. Ltd. and Palgiken Co., Ltd.

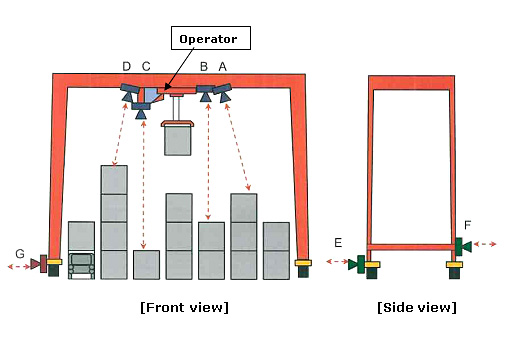

[Outlines of safety monitoring system]

- Preventing contact between containers

Sensors set in the upper parts of the crane (A. B. C. D) measure distances between the crane and the upper part of the tiered containers, to prevent contact and falling like dominoes among containers during loading/unloading. - Prevent contact between crane/crane and vehicles

The sensors in the lower part of the crane (E, F, G) measure the relative distance between the crane and other cranes, and the crane and vehicle, and limit the crane's maximum speed within that distance as needed to prevent contact accidents.

- Main features of microwave

-

A) Less susceptible to weather (wind and rain, fog, air density), compared to conventional radar and ultrasonic sensors.

-

B) Can measure distance more reliably, without regard to shapes of objects, because the microwaves cover a larger area than radar.

-

C) Can measure longer distances than radar and ultrasonic sensors.

-

D) License application for a radio frequency is not needed when installing the system, because it conforms to the 24GHz band specified low power radio certification.

-