- JP

- EN

MOL Completes Concept for Series of New-Generation Vessels

-Third in the Series: ISHIN-III Large-Scale Iron Ore Carrier-

April 08, 2010

TOKYO - Mitsui O.S.K. Lines, Ltd. (MOL, President: Akimitsu Ashida) today announced the completion of the concept for its third in a series of next-generation vessels, which will be technically practical in the near future. The latest concept is for an environment-friendly, large-scale iron ore carrier called the ISHIN-III that will play a key role in future resource transport.

MOL already operates the very large iron ore carrier Brasil Maru that offers a high level of environmental performance thanks to its pioneering transport concept and innovative technologies. Delivered in December 2007, the 320,000-DWT Brasil Maru (Length: 340m; width: 60m; main engine output: 23,000kW) is one of the world's largest iron ore carriers, and was named the Ship of the Year 2007 by The Japan Society of Naval Architects and Ocean Engineers for its energy-saving, safety, and high technical performance. The ISHIN-III, which makes full use of the characteristics of that vessel class, is a highly viable concept, aiming to further reduce MOL's environmental burden by maximizing the use of technologies the company has developed and adopted.

ISHIN-III's two main features are as follows:

(1) Waste heat energy recovery to assist propulsion

The new concept seeks to maximize waste heat energy recovery with more advanced technology. A large amount of heat energy can be recovered from the large main engine's exhaust gas, converted to electricity, and utilized to provide additional propulsion, significantly reducing the vessel's environmental burden. This technology can also be applied to large main engines installed on tankers and containerships.

(2) Reduction of CO2 emissions even at low speeds

The combination of a turbocharger that can operate at high efficiency even at low rpm and an electronically-controlled main engine reduces CO2 emissions even during a low-speed voyage.

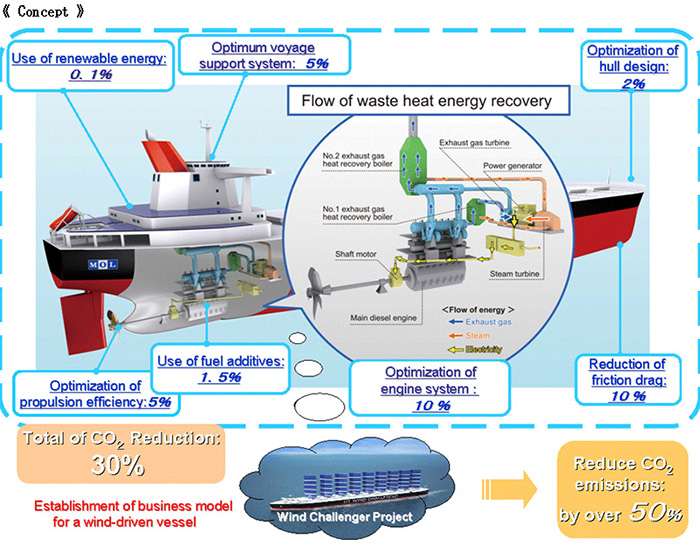

By introducing (1) and (2) and adopting a combination of new technologies, CO2 emissions will be reduced by 30%.

Overall CO2 emissions can be reduced by over 50% when a business model for a "Wind Challenger Project" is established. The project is development of a wind-driven vessel, led by Tokyo University, MOL, shipbuilder, material maker, Nippon Kaiji Kyokai, and other ocean shipping companies.

MOL named the first concept vessel "ISHIN-I (ishin one)," which stands for "Innovations in Sustainability backed by Historically proven, INtegrated technologies." In addition, ishin is the Japanese word for a complete revitalization or reform.

Main CO2 reduction technologies

-

Optimization of engine system

- (1)Waste heat energy recovery to assist propulsion

The exhaust gas turbine and steam turbine driven by waste heat energy recovered from the main engine exhaust gas efficiently produce electricity for auxiliary motors on the propeller shaft, providing additional propulsion force. - (2)Reduction of CO2 emissions even during a low-speed voyage

The combination of the turbocharger that can operate at high efficiency even at low rpm and the electronically-controlled main engine reduces CO2 emissions even during a low-speed voyage.

- (1)Waste heat energy recovery to assist propulsion

- Use of fuel additive

The TAICRUSH HD fuel additive jointly developed by MOL Technology Research Center and Taihokohzai Co., Ltd. ensures more effective ignition and combustion of fuel oil. - Reduction of friction drag

The ISHIN-III will adopt the next-generation ultra-low friction ship bottom coating, in which smooth micro patterned indentations form on the painted surface, trapping water and reducing friction drag. - Optimum voyage support system

This system receives the latest marine weather information while monitoring voyage conditions, and searches for the shortest and most fuel-efficient route, in consideration of the vessel's unique characteristics. - Optimization of propulsion efficiency

The Propeller Boss Cap Fins (PBCF), an MOL-developed energy-saving device, has been adopted on more than 1,700 vessels all over the world. The upgraded model and high-efficiency propellers will be installed on the ISHIN-III vessels. - Optimization of hull design

A drastically improved hull form below the surface will enhance fuel efficiency. - Use of renewable energy

Solar battery panels will be installed on the aft decks. The electricity generated while under way will be used for part of the propulsion force and/or stored in the high-capacity rechargeable lithium ion batteries. This stored electricity can be used while the vessel is in port or berthed.