- JP

- EN

MOL to Harness Big Data to Enhance Engine Plant Preventive Maintenance and Reduce Life Cycle Costs

- 2 Newbuilding Vessels to be Equipped with Next-generation Engine Status Monitoring System with Upgraded Functions -

July 19, 2017

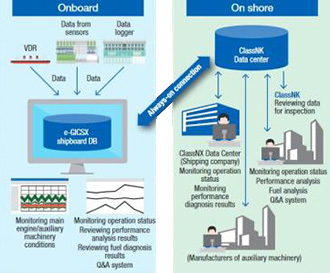

-Image of ClassNK CMAXS-

Using the operation monitoring system, it detects predictive abnormalities in the engine, which are hard to be recognized by crewmembers, to prevent engine trouble and minimize downtime.

TOKYO-Mitsui O.S.K. Lines, Ltd. (MOL; President & CEO: Junichiro Ikeda) today announced the company's intent to install the "ClassNK CMAXS", next-generation engine status monitoring system developed by ClassNK Consulting Services Co., Ltd. (CEO & President: Daikichi Nomura; Headquarters: Tokyo), on two newbuilding vessels.

The two target vessels will be equipped with the main engine data analysis function "CMAXS e-GICSX" (Note 1), from Mitsui Engineering & Shipbuilding Co., Ltd. (MES; President: Takao Tanaka), on a CMAXS common platform system that can simultaneously operate and manage the main engine, power generator, and auxiliaries. The system is also combined with the "CMAXS-LCA" engine operation support service for the generator, supplied by Daihatsu Diesel Mfg. Co., Ltd. (President: Shigeki Kinoshita, Headquarters: Osaka). In addition, more and various remote supervision sensors will be equipped with generators, to aim at more accurate generator status monitoring and improved automatic diagnosis by "CMAXS-LCA".

Under the "ISHIN NEXT - MOL SMART SHIP PROJECT" (Note2), announced in November 2016, MOL is collecting and centralizing big data on board its operated vessels, with the goal of establishing an integrated vessel operation support network that allows timely analysis of results on shore and at sea through marine onboard broadband systems. This network will support vessel operation, reduce environmental impact, improve efficient navigation, and streamline vessel management, in addition to other benefits. The project announced today is part of this initiative.

(Note 1)

The system relies on early detection of abnormalities in the electronically controlled engine to ensure correct preventive maintenance and reduce life cycle costs. For details, please refer to the press release on October 8, 2015: "Using Big Data for Engine Preventive Maintenance and Reduction of Life Cycle Costs"

(Note 2)

Press release on November 24, 2016: MOL Launches "ISHIN NEXT - MOL SMART SHIP PROJECT -"